(ROSENBERG, Texas) – With nearly every industry needing some form of machined part, gaining a degree in precision machining can lead to many open doors and high-paying careers.

That is precisely what Texas State Technical College’s Precision Machining Technology program is designed to help students achieve.

The program is structured to build knowledge from the basics to more advanced techniques near the end. In the first semester, students are taught manual machining and how to read blueprints. Understanding what the drawings and details mean is crucial to making parts correctly. After that, students focus on how to read instruments in both metric and imperial systems.

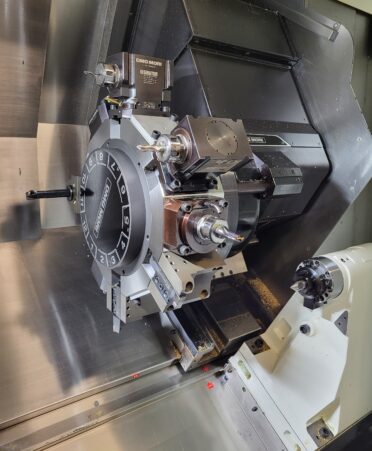

The second semester is when students begin working with the CNC, or computer numerical control, machines. They focus on learning G and M codes, which are the code types that the machines run on. By the last semester, students are tested on what they know, making parts and projects with minimal instructor oversight.

“The students are able to choose not only what part they want to make, but also what type of machine they want to make it on,” said Deogratias Nizigiyimana, lead instructor for the Precision Machining Technology program at TSTC’s Fort Bend County campus. “What we as instructors then do is make sure they haven’t made any errors.”

The program teaches students how to machine parts in both metal and other materials such as plastics. While some materials such as wood are not normally used in lab sessions, Nizigiyimana stated that students would have no trouble machining them as the principles behind the process remain the same.

“What type of companies are hiring machinists depends on location,” Nizigiyimana said. “Most of the students from this campus end up working in the oil and gas field. But students from other campuses may end up working more for machine or vehicle manufacturing.”

Despite certain industries doing a bulk of the hiring, however, machinists are needed everywhere. Anytime a precise cut needs to be made, or a unique shape or object needs to be fabricated, machinists are in demand.

“Machinists are everywhere,” Nizigiyimana said. “For every beam that needs welding, they are first taken to a machine shop to be cut to the right angle. Wherever you see a weld, machinists are also involved.”

Many TSTC instructors come from backgrounds working in the fields they teach, which allows them to know the ins and outs of their programs.

Nizigiyimana worked as a machinist for 12 years before becoming an instructor at Lone Star College. After two years of teaching there, he moved to TSTC in 2016.

“I love my job as an instructor,” he said. “I spend a lot of time preparing to teach my students. I want to make sure that they are ready to work on day one.”

In Texas, CNC tool programmers earn a median annual salary of $61,740 per year, according to onetonline.org. The website projected a 47% increase in the number of these jobs in the state from 2020 to 2030.

TSTC’s Precision Machining Technology program offers an Associate of Applied Science degree and two certificates of completion. The program is taught at the East Williamson County, Fort Bend County, Harlingen, Marshall, North Texas and Waco campuses.

Precision Machining Technology is one of nine Money-Back Guarantee programs in which tuition is refunded if the participating graduate has not found employment in their field of study within six months of graduation. For more information about the guarantee, visit tstc.edu/mbg.

Registration for TSTC’s fall semester is underway. For more information, go to tstc.edu.